Revolutionising Water Filtration with AFM Media: A Sustainable Solution

In the realm of water filtration, innovation is the key to addressing pressing environmental concerns. Introducing AFM media – a groundbreaking hydrophobic surface engineered to tackle the absorption of organics and microplastics with unparalleled efficiency. AFM®, an inert, amorphous aluminosilicate (glass), represents a leap forward in sustainable filtration technology, crafted through the upcycling of postconsumer green and brown glass bottles.

Innovative Manufacturing Process

At the heart of AFM lies a meticulously designed manufacturing process. State-of-the-art facilities, purpose-built to produce activated glass water filtration media, ensure the highest quality standards are met. This dedication to excellence is evident in every facet of AFM’s creation.

Versatile Applications for

AFM media

AFM is not just another filter media; it’s a versatile solution catering to a spectrum of water treatment needs. Whether it’s ground water, surface water, seawater, or waste water treatment, AFM media stands ready to deliver exceptional results. Its compatibility with both single and dual media filtration systems, regardless of whether they are open (RGF) or closed (pressure) filters, underscores its adaptability and reliability.

Applications AFM ng

- Polishing step

- Pre treatment UF/RO

- Fine filtration

- Cooling & heating tower

- Process water

- Wastewater treatment

Features and Benefits

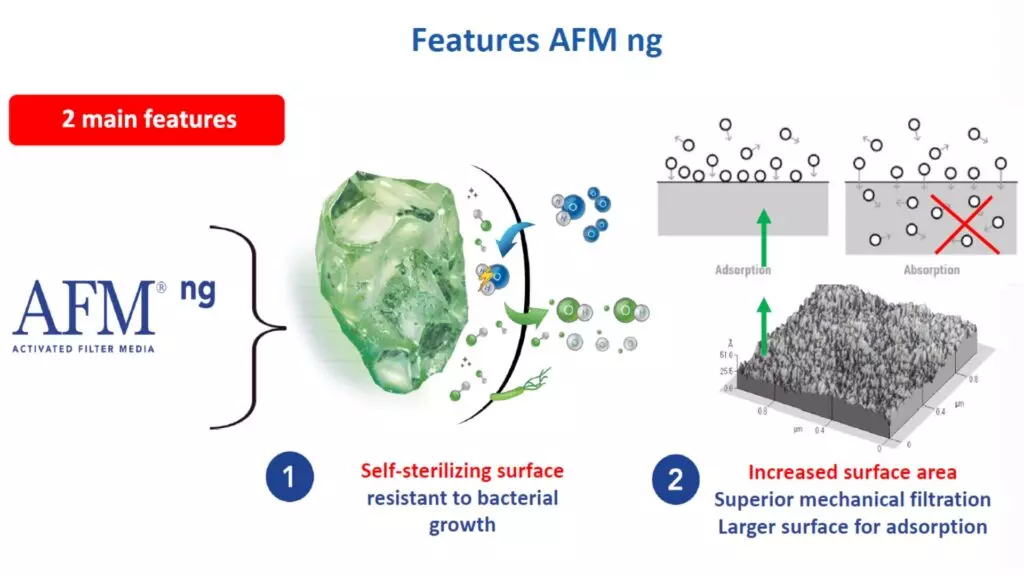

The distinguishing features of AFM media are as impressive as they are essential:

- Self-Sterilising Surface: Resistant to bacterial growth, ensuring the delivery of safe, clean water.

- Increased Surface Area: Enhances filtration properties, promoting superior performance.

- Activated Surface: Facilitates the adsorption of fine particles and organic matter, guaranteeing optimal filtration efficiency.

The benefits of incorporating AFM into water treatment systems are manifold:

- Safe Water: Prevents the transmission of pathogens, safeguarding public health.

- Clear Water: Maintains a stable 1-micron filtration rate, ensuring water clarity.

- Low Operating Costs: Saves resources such as backwash water and chemicals, contributing to cost efficiency.

- Patented Activation Process: A three-step activation process endows AFM® with self-sterilising properties and superior filtration performance.

- Sustainability at its core.

AFM isn’t just a filtration media; it’s a commitment to sustainability. By conserving resources such as water, chlorine, and energy through efficient backwash processes, AFM® offers a sustainable alternative to traditional filtration methods. Its longevity ensures a guaranteed return on investment, making it a sound choice for environmentally conscious organisations.

Certified Excellence

Manufactured under ISO9001-2015 conditions, AFM® adheres to the highest quality standards. Endorsed by DWI EC Reg31, NSF50 & NSF61, and HACCP certifications, AFM® is trusted for use in swimming pools, potable water, and food and drink markets. Its reliability and safety are unparalleled, providing peace of mind to consumers and industries alike.

Conclusion

In the pursuit of clean water solutions, AFM stands out as a beacon of innovation and sustainability. Its advanced filtration capabilities, coupled with its eco-friendly manufacturing process and certifications, make it a compelling choice for addressing the challenges of modern water treatment. Join us in embracing the future of filtration with AFM, where excellence meets sustainability for a cleaner, healthier world.

AFM Media is now available from Wycombe Water. AFM is suitable for pre-treatment before a Reverse Osmosis or an Ultra-filtration system. It’s also applicable for drinking water and wastewater treatment. Even cooling & heating tower applications will benefit from AFM.

Discover the transformative benefits of AFM media with Wycombe Water, specialists in commercial and industrial water treatment equipment.

Tel: 01296 332650

Email: sales@wycombewater.co.uk

YOU’RE INVITED!

Are you eager to discover more about cutting-edge filtration technology?

Join us for an exclusive tour on April 18, 2024, and witness firsthand the world’s most sophisticated glass filter media manufacturing process at Dryden Aqua, located at 3 Butterfield Industrial Estate, Bonnyrigg, Edinburgh EH19 3JG.

Space is limited, so secure your spot by sending us an email at sales@wycombewater.co.uk. Don’t miss this opportunity to delve into the future of water filtration!